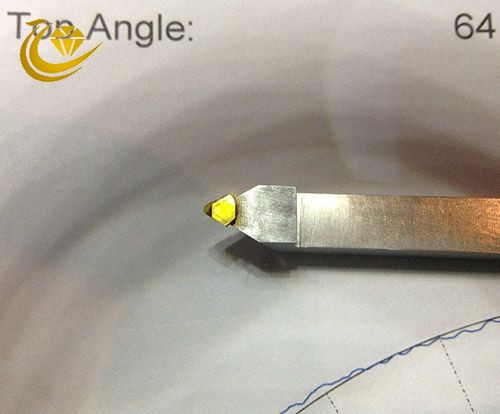

Single Crystal Diamond Plates SCDP series

SCDP series Single Crystal Diamond Plates has high hardness, good wear resistance, impact toughness, good thermal conductivity, high finish, and non-ferrous metal friction coefficient is low, good adhesion resistance and excellent thermal stability and chemical stability, can grind extremely sharp edge, is the most ideal ultra-precision cutting......

We're here to help:Easy ways to get the answers you need.

PRODUCT LIST

- Single crystal superhard material

- Large Single Crystal Diamond Big Size Single Crystal Diamond BCD seriesSingle Crystal Diamond Plates SCDP series

- Single Crystal Diamond Coarse Synthetic Diamond CSD seriesFine Synthetic Diamond FSD seriesResin Bond Diamond AC series

- Crushed & Reshaped Diamond Powder Crushed Diamond Powder CCSD seriesReshaped Diamond Powder RCSD seriesPolycrystalline Diamond Abrasives APC4 series

- Diamond Micron Powder General Diamond Micron Powder CSDM seriesSpecial Diamond Micron Powder CSDM series As Grown Diamond Micron Powder ASM series Polycrystalline Diamond Micron Powder CSDM-PD series

- CBN (Cubic Boron Nitride) CBN MonocrystalCBN Micron Powder

- Coated Diamond and CBN Coated Diamond and CBN

- Polycrystalline Superhard Materials

- PCD (Polycrystalline Diamond) PCD Blanks for Wire Drawing DiesPCD Wire Drawing DiesPCD Blanks for Cutting ToolsPCD Cutting Tools

- PDC (Polycrystalline Diamond) PDC Cutters for Oil & GasPDC Cutters for MiningPDC Cutters for StoneThermally Stable PCD(TSP)

- PCBN (Polycrystalline Cubic Boron Nitride) Solid PCBN Cutting ToolsCarbide Supported PCBN CompactsPCBN Soldering Cutting Tools

- CVD Diamond CVD Blanks for Wire Drawing DiesCVD Blanks for DressingCVD Blanks for Cutting ToolsCVD Blanks for Thermal ManagementCVD Blanks for Optical Windows

Size Chart

|

Grades

Specifications, MM |

SCDP-A1 |

SCDP-A2 |

SCDP-B1 |

SCDP-B2 |

SCDP-C1 |

SCDP-C2 |

|

2.5*2.5*1.0 |

Y |

Y |

Y |

Y |

Y |

Y |

|

3.0*3.0*1.0 |

Y |

Y |

Y |

Y |

Y |

Y |

|

3.5*3.5*1.0 |

Y |

Y |

Y |

Y |

Y |

Y |

|

4.0*4.0*1.0 |

Y |

Y |

Y |

Y |

Y |

Y |

|

4.5*4.5*1.0 |

Y |

Y |

Y |

Y |

Y |

Y |

|

5.0*5.0*1.0 |

Y |

Y |

Y |

Y |

Y |

Y |

|

5.5*5.5*1.0 |

Y |

Y |

Y |

Y |

Y |

Y |

|

6.0*6.0*1.0 |

Y |

Y |

Y |

Y |

Y |

Y |

|

6.5*6.5*1.0 |

Y |

Y |

Y |

Y |

Y |

Y |

|

7.0*7.0*1.0 |

Y |

Y |

Y |

Y |

Y |

Y |

Comparison

Inquiry

PRODUCTS:

Copyright © 2018 Henan Baililai Superhard Materials Co., Ltd. All rights reserved. Powered by MetInfo

TOP

简体中文

简体中文 English

English Pусский

Pусский

.jpg)

Description

SCDP series Single Crystal Diamond Plates has high hardness, good wear resistance, impact toughness, good thermal conductivity, high finish, and non-ferrous metal friction coefficient is low, good adhesion resistance and excellent thermal stability and chemical stability, can grind extremely sharp edge, is the most ideal ultra-precision cutting tool material. As the tool material, its performance is far more than carbide, Diamond composite sheet and other cutting tool material, with natural diamond cutting tool material comparable to the new era of cutting tool material.

Application areas:

SCDP series Single Crystal Diamond Plates is the ideal material for precision machining in automobile, machine tool, bearing, tool, hydraulic and other industries; also used in aerospace, optical materials, jewelry processing, watches, instruments, instrument manufacturing, fiber optic cable infrared and other high-tech fields.

Main uses:

1, Metal processing:cast iron disc grinding;

2, Non-ferrous metal turning such as; Gold, Silver, Aluminum, aluminum, copper, etc.;

3, Non-ferrous, non-metallic materials cutting tools: optical materials, ceramics, various fiber and particle reinforced composite materials, plastic, rubber, graphite, glass and a variety of wear-resistant wood (solid wood, plywood, MDF and other composite materials);

4, Grinding wheel Dressing pen;

5, Wear parts;

6, A variety of special tools, grinding tools such as: forming knife, grinding wheel knife, turning knife, turning knife, Diamond pen, carving knife, batch knife, angle knife, elastic knife, sharp knife, knife and other tools;

7, Single crystal drawing die;

8, Cutting flat glass (such as mobile phone screen, etc);

Depending on the direction of the crystal, size, thickness, purity, the number of right angles and the range of applications, we can provide square, rectangular, round, and triangular specifications.

SCDP-A:

Observed under a microscope without any inclusions.

SCDP-B:

Observed under a microscope to see trace inclusions.

SCDP-C:

In the light observation can see a small number of inclusions.