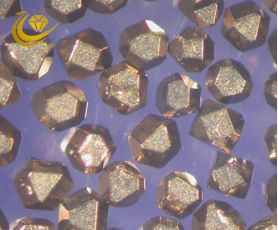

Coarse Synthetic Diamond CSD series

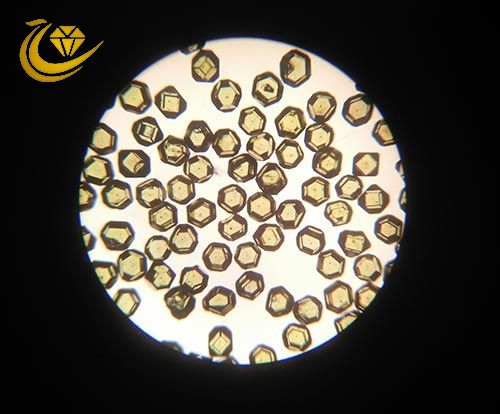

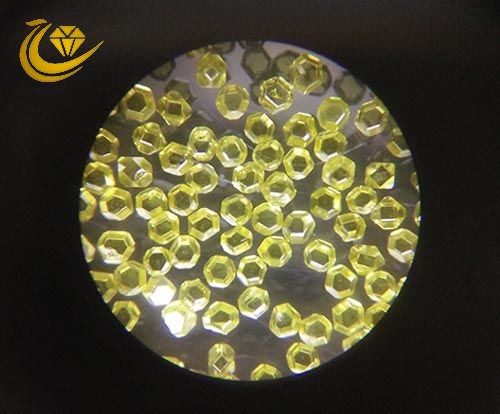

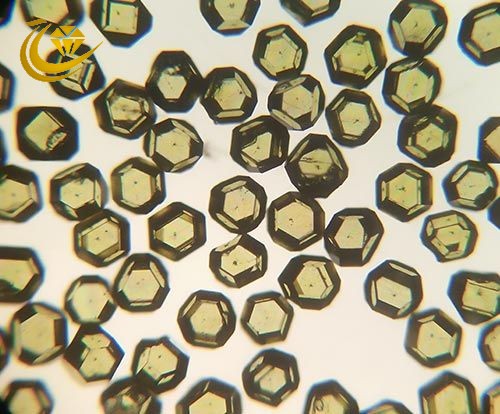

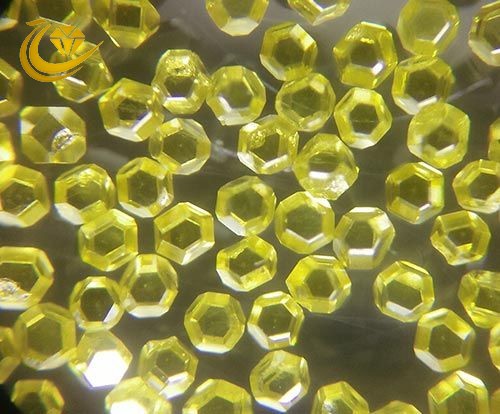

Our CSD series Single Crystal Synthetic Diamond refers to the particle size of 20/25 to 50/60 coarse-grained diamond. this series of products is the golden crystal, the crystal is complete and into the six-octahedral structure, impurity content, degree of transparency, and has superior static strength, impact toughness and thermal stability.

We're here to help:Easy ways to get the answers you need.

PRODUCT LIST

- Single crystal superhard material

- Large Single Crystal Diamond Big Size Single Crystal Diamond BCD seriesSingle Crystal Diamond Plates SCDP series

- Single Crystal Diamond Coarse Synthetic Diamond CSD seriesFine Synthetic Diamond FSD seriesResin Bond Diamond AC series

- Crushed & Reshaped Diamond Powder Crushed Diamond Powder CCSD seriesReshaped Diamond Powder RCSD seriesPolycrystalline Diamond Abrasives APC4 series

- Diamond Micron Powder General Diamond Micron Powder CSDM seriesSpecial Diamond Micron Powder CSDM series As Grown Diamond Micron Powder ASM series Polycrystalline Diamond Micron Powder CSDM-PD series

- CBN (Cubic Boron Nitride) CBN MonocrystalCBN Micron Powder

- Coated Diamond and CBN Coated Diamond and CBN

- Polycrystalline Superhard Materials

- PCD (Polycrystalline Diamond) PCD Blanks for Wire Drawing DiesPCD Wire Drawing DiesPCD Blanks for Cutting ToolsPCD Cutting Tools

- PDC (Polycrystalline Diamond) PDC Cutters for Oil & GasPDC Cutters for MiningPDC Cutters for StoneThermally Stable PCD(TSP)

- PCBN (Polycrystalline Cubic Boron Nitride) Solid PCBN Cutting ToolsCarbide Supported PCBN CompactsPCBN Soldering Cutting Tools

- CVD Diamond CVD Blanks for Wire Drawing DiesCVD Blanks for DressingCVD Blanks for Cutting ToolsCVD Blanks for Thermal ManagementCVD Blanks for Optical Windows

Size Chart

|

Grade

Size |

CSD10 |

CSD20 |

CSD30 |

CSD40 |

CSD50 |

CSD60 |

CSD70 |

CSD80 |

CSD90 |

|

20/25 |

Y |

Y |

Y |

Y |

Y |

Y |

Y |

Y |

Y |

|

25/30 |

Y |

Y |

Y |

Y |

Y |

Y |

Y |

Y |

Y |

|

30/35 |

Y |

Y |

Y |

Y |

Y |

Y |

Y |

Y |

Y |

|

35/40 |

Y |

Y |

Y |

Y |

Y |

Y |

Y |

Y |

Y |

|

40/45 |

Y |

Y |

Y |

Y |

Y |

Y |

Y |

Y |

Y |

|

45/50 |

Y |

Y |

Y |

Y |

Y |

Y |

Y |

Y |

Y |

|

50/60 |

Y |

Y |

Y |

Y |

Y |

Y |

Y |

Y |

Y |

Comparison

|

BAILILAI

GB/T6406-1995 |

USA

ANSI US Mesh # |

EC

FEPA D |

International standard

ISO |

Russia

GOST9206-80 |

|

20/25 |

20/25 |

D851 |

850/710 |

850/710 |

|

25/30 |

25/30 |

D711 |

710/600 |

710/600 |

|

30/35 |

30/35 |

D601 |

600/500 |

630/500 |

|

35/40 |

35/40 |

D501 |

500/425 |

500/400 |

|

40/45 |

40/45 |

D426 |

425/355 |

400/315 |

|

45/50 |

45/50 |

D356 |

355/300 |

400/315 |

|

50/60 |

50/60 |

D301 |

300/250 |

315/250 |

Inquiry

Related Products

PRODUCTS:

Copyright © 2018 Henan Baililai Superhard Materials Co., Ltd. All rights reserved. Powered by MetInfo

TOP

简体中文

简体中文 English

English Pусский

Pусский

.jpg)

Description

Our CSD series Single Crystal Synthetic Diamond refers to the particle size of 20/25 to 50/60 coarse-grained diamond. this series of products is the golden crystal, the crystal is complete and into the six-octahedral structure, impurity content, degree of transparency, and has superior static strength, impact toughness and thermal stability. mainly used for manufacturing cutting tools, drilling tools, and soldering welding tool, etc., widely used in stone processing, construction, road and bridge, glass processing, oil and gas drilling, mechanical processing and jewelry processing and other industries.

CSD90

Features: crystal type complete, rules of the six-octahedron, the crystal within almost no impurities, with high static strength, Newton, and impact toughness of TI, and the thermal stability of the TTI, the overall performance reached the International same product level, the wear resistance is excellent.

Uses: suitable for very high work intensity under the condition of cutting tools, drilling tools and brazing tools and the like; such as high strength reinforced concrete, asphalt pavement and a very high hardness of granite (F=20 the cutting and drilling, as well as the performance of geological engineering drill bit.

CSD80

Features: crystal type complete, rules of the six-octahedron, the crystal impurity content is very small, having a very high static strength, Newton, and impact toughness of TI, and the thermal stability of the TTI, the wear resistance is very good.

Uses: suitable for high work intensity under the condition of cutting tools, drilling tools, brazing tools, and electroplating tools; such as reinforced concrete, high hardness granite (F=15 and high hardness ceramic material cutting and punching, as well as engineering drill, etc.

CSD70

Features: crystal form a complete, six-octahedron, the crystal impurity content of less, has a high static strength, Newton, and impact toughness of TI, and the thermal stability of the TTI, and good wear resistance.

Uses: suitable for high work intensity under the condition of cutting tools, drilling tools, brazing tools, and electroplating tools; such as concrete, hard granite (F=10, a high-end tile and high hardness of the refractory material cutting and punching; and a heavy load of the grinding tool and the high load of the plating brazing tools and the like.

CSD60

Features: crystal form a complete, six-octahedron, the crystal impurity content of less, has a high static strength, Newton, and impact toughness of TI, and the thermal stability of the TTI, and good wear resistance.

Uses: suitable for high work intensity under the condition of cutting tools, drilling tools, brazing tools, and electroplating tools; such as concrete, hard granite (F=10, a high-end tile and high hardness of the refractory material cutting and punching; and a heavy load of the grinding tool and the high load of the plating brazing tools and the like.

CSD50

Features: crystal-less rules, six-octahedron, crystals within the medium content of impurities, with the general static strength, Newton, and impact toughness of TI, and the thermal stability of the TTI, the wear resistance of the medium, sharpness is good.

Uses: suitable for low working strength under conditions of high speed cutting and drilling, such as soft marble and Sandstone F=6-5, the glass, ceramic and bulk construction material cutting and punching; and a medium load of the grinding tools and in the low load of the electroplating tool, etc.

CSD40

Features: crystal type 90-95% of the rules, within the crystal medium content of impurities having a lower static strength, Newton, and impact toughness of TI, and the thermal stability of the TTI, and wear resistance in General, sharpness is very good.

Uses: suitable for low working strength under conditions of high speed cutting and drilling, such as small diameter free-cut punch tool; and low-load grinding tools and low load of the electroplating tool, etc.

CSD30

Features: Polymorph 85% of rules within the crystal impurity content of more than CSD40, having a lower static strength, Newton, and impact toughness of TI, and the thermal stability of the TTI, the wear resistance is poor, sharpness is very good.

Uses: suitable for good sharpness of the small diameter of free-cutting tools and punching tools, such as gem, Jade, crystal and other high-brittle materials and small quantities of stone, glass, tile cutting and drilling; and low-load grinding tools and low load of the electroplating tool, etc.

CSD20

Features: crystal form 70% of the rules, within the crystal impurity content of more, the surface roughness, has a low static strength, Newton, and impact toughness of TI, and the thermal stability of the TTI, the wear resistance is poor, sharpness is excellent.

Uses: suitable for good sharpness of the small diameter of free-cutting tools and punching tools, in a high load of ceramic binding Agent tools, low-load metal-bond grinding tool and the sharpness very high plating tool; means for processing hard alloy, magnetic material, glass, ceramic tile, crystal, precious stones and other brittle material; also available with higher-grade the diamond use, adjust the tool sharpness.

CSD10

Features: polymorphs 50% rule, within the crystal impurity content, surface roughness, having a very low static strength, Newton, and impact toughness of TI, and the thermal stability of the TTI, the wear resistance is poor, sharpness is excellent, self-sharpening good.

Uses: suitable for high-load resin bonded grinding tool, low load ceramic bond tool, low-load metal-bond grinding tool and the sharpness very high resin bond tool, used for processing hard alloy, magnetic material, glass, ceramic tile, crystal, precious stones and other brittle material; also available with higher-grade the diamond use, adjust the tool sharpness.