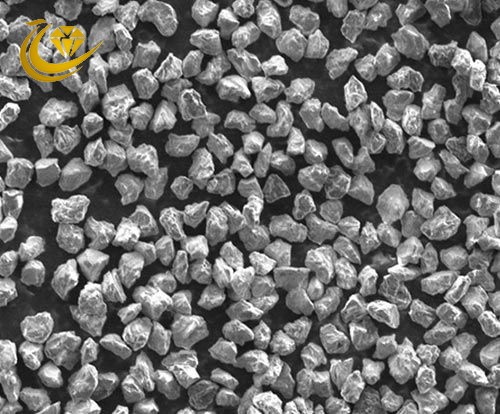

Polycrystalline Diamond Micron Powder CSDM-PD series

CSDM-PD series Polycrystalline Diamond Micron powder, as a transient ultra-high pressure, high temperature detonation synthesis of nano-diamond aggregates, is similar to the nature of a small meteorite found in black diamond. It is composed of cubic diamond and hexagonal diamond compact is composed of polycrystalline.......

We're here to help:Easy ways to get the answers you need.

PRODUCT LIST

- Single crystal superhard material

- Large Single Crystal Diamond Big Size Single Crystal Diamond BCD seriesSingle Crystal Diamond Plates SCDP series

- Single Crystal Diamond Coarse Synthetic Diamond CSD seriesFine Synthetic Diamond FSD seriesResin Bond Diamond AC series

- Crushed & Reshaped Diamond Powder Crushed Diamond Powder CCSD seriesReshaped Diamond Powder RCSD seriesPolycrystalline Diamond Abrasives APC4 series

- Diamond Micron Powder General Diamond Micron Powder CSDM seriesSpecial Diamond Micron Powder CSDM series As Grown Diamond Micron Powder ASM series Polycrystalline Diamond Micron Powder CSDM-PD series

- CBN (Cubic Boron Nitride) CBN MonocrystalCBN Micron Powder

- Coated Diamond and CBN Coated Diamond and CBN

- Polycrystalline Superhard Materials

- PCD (Polycrystalline Diamond) PCD Blanks for Wire Drawing DiesPCD Wire Drawing DiesPCD Blanks for Cutting ToolsPCD Cutting Tools

- PDC (Polycrystalline Diamond) PDC Cutters for Oil & GasPDC Cutters for MiningPDC Cutters for StoneThermally Stable PCD(TSP)

- PCBN (Polycrystalline Cubic Boron Nitride) Solid PCBN Cutting ToolsCarbide Supported PCBN CompactsPCBN Soldering Cutting Tools

- CVD Diamond CVD Blanks for Wire Drawing DiesCVD Blanks for DressingCVD Blanks for Cutting ToolsCVD Blanks for Thermal ManagementCVD Blanks for Optical Windows

Size Chart

|

Grade

Size |

CSDM -PD |

Median

D50 (μm) |

|

0-0.15 |

Y |

0.07 |

|

0-0.2 |

Y |

0.1 |

|

0-0.25 |

Y |

0.125 |

|

0-0.5 |

Y |

0.25 |

|

0-1 |

Y |

0.5 |

|

0-2 |

Y |

1 |

|

1-3 |

Y |

2 |

|

2-4 |

Y |

3 |

|

2-6 |

Y |

4 |

|

3-7 |

Y |

5 |

|

4-8 |

Y |

6 |

|

5-10 |

Y |

7 |

|

6-10 |

Y |

8 |

|

6-12 |

Y |

9 |

|

8-16 |

Y |

14 |

|

12-22 |

Y |

17 |

Comparison

Inquiry

PRODUCTS:

Copyright © 2018 Henan Baililai Superhard Materials Co., Ltd. All rights reserved. Powered by MetInfo

TOP

简体中文

简体中文 English

English Pусский

Pусский

.jpg)

Description

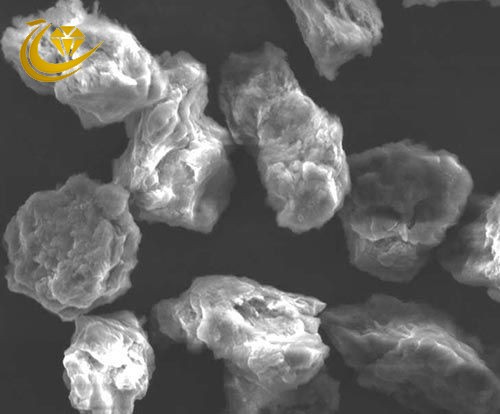

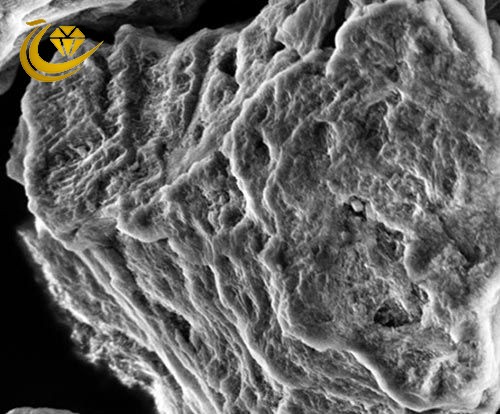

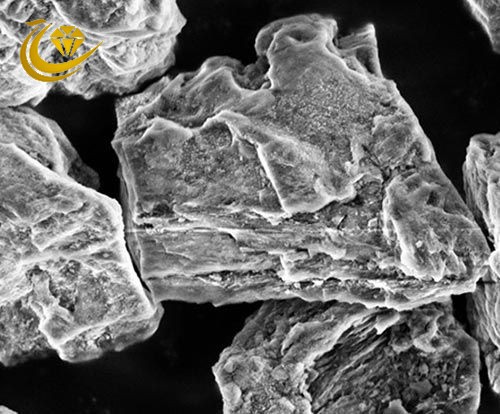

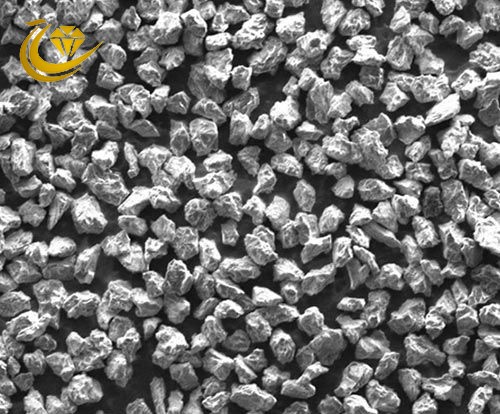

CSDM-PD series Polycrystalline Diamond Micron powder, as a transient ultra-high pressure, high temperature detonation synthesis of nano-diamond aggregates, is similar to the nature of a small meteorite found in black diamond. It is composed of cubic diamond and hexagonal diamond compact is composed of polycrystalline body having high toughness, high self-sharpening and high hardness and other characteristics, as a new abrasive material, on a sapphire polishing processing and other aspects there are other materials irreplaceable advantages. grinding efficiency is a single crystal diamond 2~4 times, and does not produce scratches, high degree of finish, in the electronic, aerospace, aviation and other high-tech fields have a wide range of applications.

CSDM-PD series polycrystalline diamond powder, as a transient ultra-high pressure, high temperature detonation synthesis of nano-diamond aggregates, is similar to the nature of a small meteorite found in black diamond. It is composed of cubic diamond and hexagonal diamond compact is composed of polycrystalline body having high toughness, high self-sharpening and high hardness and other characteristics, as a new abrasive material, on a sapphire polishing processing and other aspects there are other materials irreplaceable advantages. grinding efficiency is a single crystal diamond 2~4 times, and does not produce scratches, high degree of finish, in the electronic, aerospace, aviation and other high-tech fields have a wide range of applications. Since in recent years, LED and other industries the application of new technologies in the field continues to expand, polycrystalline diamond powder usage has grown significantly, increasing demand.

Product performance:

A. Detonation synthesis of polycrystalline diamond powder having expensive and rare black natural diamond of the polycrystalline structure, is dark gray, metallic luster, good toughness, there's automatic edge features.

B. Detonation synthesis of polycrystalline diamond with the impact of synthetic static pressure or natural single crystal diamond, silicon oxide, corundum and other abrasive compared to polycrystalline diamond, grinding efficiency is higher 2 to 4 times.

C. Polycrystalline diamond grinding accuracy to an unprecedented increase.

a, In the use of 2 ~ 4µm of polycrystalline diamond powder polishing of the workpiece, R<1.6 nm.

b, Using 0 ~ 0.5 µm polycrystalline diamond powder for grinding a workpiece, Ra=1.3 to 1.4 nm.

c, In the use of the 0 to 0.125 µm polycrystalline diamond powder for grinding a workpiece, Ra<0.1 nm.

D. Due to the polycrystalline diamond surface,“the mission ball”shape, it is polished surface, will not leave scratches, thereby improving the milling yield.

E. Polycrystalline diamond powder also can be prepared by chemical plating method, the plating on the workpiece(such as cylinder)of the inner wall, the wear resistance is superior to any other material.

Polycrystalline diamond powder uses:

A. The polishing of sapphire, silicon, ceramic, metal, etc.

B. Machining the magnetic Head material, anti-magnetic film(MR), a multi-layer film, a sputtering film, a molecular beam epitaxy(MBE), the ferrite and the printing plate.

C. Processing fiber optic connectors, laser rod and requires a certain optical waveguide through the other products.