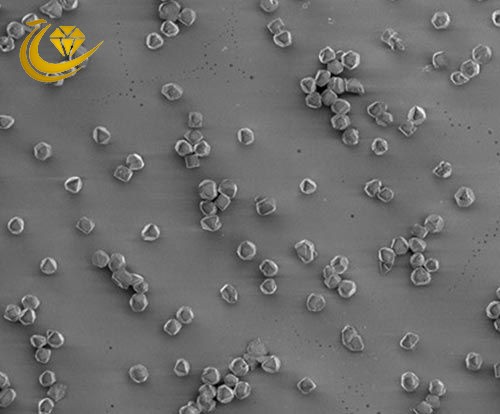

As Grown Diamond Micron Powder ASM series

ASM series as Grown Diamond Micron Powder is directly synthesized by high temperature and pressure. and different of ordinary crushing powder production methods. the advantages are as follows: 1) crystal form complete, the rules, there is no aggregate and small particles; 2) concentration of particle size distribution; 3).....

We're here to help:Easy ways to get the answers you need.

PRODUCT LIST

- Single crystal superhard material

- Large Single Crystal Diamond Big Size Single Crystal Diamond BCD seriesSingle Crystal Diamond Plates SCDP series

- Single Crystal Diamond Coarse Synthetic Diamond CSD seriesFine Synthetic Diamond FSD seriesResin Bond Diamond AC series

- Crushed & Reshaped Diamond Powder Crushed Diamond Powder CCSD seriesReshaped Diamond Powder RCSD seriesPolycrystalline Diamond Abrasives APC4 series

- Diamond Micron Powder General Diamond Micron Powder CSDM seriesSpecial Diamond Micron Powder CSDM series As Grown Diamond Micron Powder ASM series Polycrystalline Diamond Micron Powder CSDM-PD series

- CBN (Cubic Boron Nitride) CBN MonocrystalCBN Micron Powder

- Coated Diamond and CBN Coated Diamond and CBN

- Polycrystalline Superhard Materials

- PCD (Polycrystalline Diamond) PCD Blanks for Wire Drawing DiesPCD Wire Drawing DiesPCD Blanks for Cutting ToolsPCD Cutting Tools

- PDC (Polycrystalline Diamond) PDC Cutters for Oil & GasPDC Cutters for MiningPDC Cutters for StoneThermally Stable PCD(TSP)

- PCBN (Polycrystalline Cubic Boron Nitride) Solid PCBN Cutting ToolsCarbide Supported PCBN CompactsPCBN Soldering Cutting Tools

- CVD Diamond CVD Blanks for Wire Drawing DiesCVD Blanks for DressingCVD Blanks for Cutting ToolsCVD Blanks for Thermal ManagementCVD Blanks for Optical Windows

Size Chart

|

Size

Grade |

12-22 |

15-25 |

20-28 |

20-30 |

22-36 |

20-40 |

28-40 |

30-40 |

40-50 |

40-60 |

|

ASM |

Y |

Y |

Y |

Y |

Y |

Y |

Y |

Y |

Y |

Y |

Comparison

|

China standard |

International standard |

Japanese standard/ Mesh (#) |

Russia GOST9206-80 |

Median D50 (μm) |

|

w0.2 |

0-0.2 |

80000 |

|

0.1 |

|

w0.25 |

0-0.25 |

60000 |

|

0.11~0.20 |

|

w0.5 |

0-0.5 |

30000 |

0.5/0 |

0.20~0.30 |

|

w1 |

0-1 |

15000 |

1/0 |

0.6~0.8 |

|

w1.5- |

0-2 |

13000 |

|

0.8~1.0 |

|

w1.5 |

1-2 |

12000 |

2/1 |

1.1~1.3 |

|

w2.5 |

1-3 |

10000 |

|

1.6~1.8 |

|

W3 |

2-3 |

7000 |

3/2 |

1.9~2.1 |

|

w3.5 |

2-4 |

6000 |

|

2.6~3.0 |

|

W5- |

2-5 |

5000 |

5/3 |

3.1~3.4 |

|

w5 |

3-6 |

4000 |

|

3.5~4.2 |

|

W5+ |

4-6 |

3500 |

|

4.4~5.0 |

|

w7 |

4-8 |

3000 |

7/5 |

5.0~6.0 |

|

W7+ |

4-9 |

2500 |

|

6.1~6.5 |

|

w10- |

5-10 |

2000 |

10/7 |

6.5~7.3 |

|

w10 |

6-12 |

1800 |

|

7.3~8.3 |

|

w10+ |

8-12 |

1600 |

|

8.3~9.0 |

|

w14- |

7-14 |

1500 |

|

9.1~10.5 |

|

w14 |

8-16 |

1300 |

14/10 |

10.0~12.0 |

|

w20- |

10-20 |

1200 |

|

12.5~15.0 |

|

w20 |

12-22 |

1000 |

20/14 |

15.0~17.0 |

|

w20+ |

15-25 |

800 |

|

18.0~20.0 |

|

w28 |

20-30 |

700 |

28/20 |

20~23 |

|

w28+ |

22-36 |

600 |

|

23~26 |

|

w40- |

20-40 |

500 |

|

26~29 |

|

w40 |

30-40 |

450 |

40/28 |

29~32 |

|

w40+ |

35-45 |

400 |

|

32~36 |

|

w50 |

40-60 |

350 |

60/40 |

37~43 |

Inquiry

PRODUCTS:

Copyright © 2018 Henan Baililai Superhard Materials Co., Ltd. All rights reserved. Powered by MetInfo

TOP

简体中文

简体中文 English

English Pусский

Pусский

.jpg)

Description

ASM series As Grown Diamond Micron Powder is directly synthesized by high temperature and pressure. and different of ordinary crushing powder prouction methods.the advantages are as follows:

1) crystal form complete, the rules, there is no aggregate and small particles;

2) concentration of particle size distribution;

3) High strength, good wear resistance, high thermal stability;

4) High purity, impurity content of less than 0. 01% to ppm level;

5) High grinding efficiency, and can achieve good mirror effect;

6) Energy saving and long service life.

Uses:

1. Metal binding agent/D electroplated grinding wheel (grinding head, grinding wheel);

2. Manufacture of high quality PDC;

3. Diamond wire saw for uses(sapphire,SiC,GaN,Si, etc. cutting);

4. Precision cutting, grinding semiconductor, optical materials, electronic components, IT industry, automotive industry and aerospace industry.