PCD Blanks for Cutting Tools

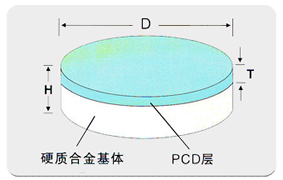

PCD Blanks for Cutting Tools is made of diamond powder and tungsten carbide substrate by high temperature and pressure sintering, both diamond wear resistance and tungsten carbide strength. PCD composite sheet has a high hardness, excellent thermal conductivity, low coefficient of friction and thermal expansion coefficient......

We're here to help:Easy ways to get the answers you need.

PRODUCT LIST

- Single crystal superhard material

- Large Single Crystal Diamond Big Size Single Crystal Diamond BCD seriesSingle Crystal Diamond Plates SCDP series

- Single Crystal Diamond Coarse Synthetic Diamond CSD seriesFine Synthetic Diamond FSD seriesResin Bond Diamond AC series

- Crushed & Reshaped Diamond Powder Crushed Diamond Powder CCSD seriesReshaped Diamond Powder RCSD seriesPolycrystalline Diamond Abrasives APC4 series

- Diamond Micron Powder General Diamond Micron Powder CSDM seriesSpecial Diamond Micron Powder CSDM series As Grown Diamond Micron Powder ASM series Polycrystalline Diamond Micron Powder CSDM-PD series

- CBN (Cubic Boron Nitride) CBN MonocrystalCBN Micron Powder

- Coated Diamond and CBN Coated Diamond and CBN

- Polycrystalline Superhard Materials

- PCD (Polycrystalline Diamond) PCD Blanks for Wire Drawing DiesPCD Wire Drawing DiesPCD Blanks for Cutting ToolsPCD Cutting Tools

- PDC (Polycrystalline Diamond) PDC Cutters for Oil & GasPDC Cutters for MiningPDC Cutters for StoneThermally Stable PCD(TSP)

- PCBN (Polycrystalline Cubic Boron Nitride) Solid PCBN Cutting ToolsCarbide Supported PCBN CompactsPCBN Soldering Cutting Tools

- CVD Diamond CVD Blanks for Wire Drawing DiesCVD Blanks for DressingCVD Blanks for Cutting ToolsCVD Blanks for Thermal ManagementCVD Blanks for Optical Windows

Size Chart

|

Product range |

Diameter D, mm |

Total Thickness H, mm(+/-0.05) |

Diamond Layer Thickness T, mm (+/-0.1) |

|

PCD-02 |

ф45/ф55 |

1.6/2.0/3.2 |

0.5 |

|

PCD-05 |

ф45/ф55 |

1.6/2.0/3.2 |

0.5 |

|

PCD-10 |

ф45/ф55 |

1.6/2.0/3.2/5.0 |

0.5/1.0 |

|

PCD-25 |

ф45/ф55 |

1.6/2.0/3.2/5.0 |

0.5/1.0 |

|

PCD-302 |

ф45/ф55 |

1.6/2.0/3.2/5.0 |

0.5/1.0 |

Note: the above specifications can be cut into various shapes according to customer needs.

Comparison

Inquiry

Related Products

PRODUCTS:

Copyright © 2018 Henan Baililai Superhard Materials Co., Ltd. All rights reserved. Powered by MetInfo

TOP

简体中文

简体中文 English

English Pусский

Pусский

.jpg)

Description

PCD Blanks for Cutting Tools is made of diamond powder and tungsten carbide substrate by high temperature and pressure sintering, both diamond wear resistance and tungsten carbide strength. PCD Blanks for Cutting Tools has a high hardness, excellent thermal conductivity, low coefficient of friction and thermal expansion coefficient, and between non-ferrous metals and non-metallic materials have a greater chemical inertness.It has been widely used in automobile engine and its accessories, high precision medical equipment, precision electronic components, aerospace equipment and other fields.

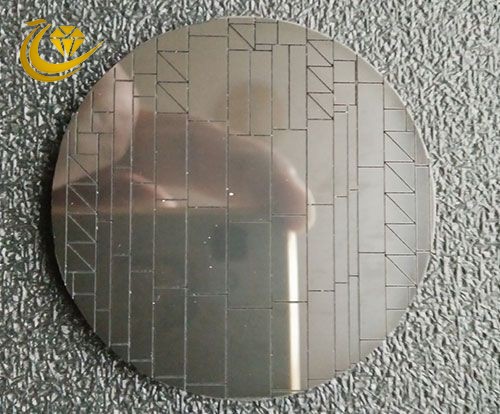

My company's production of PCD composite blank using high-quality diamond powder as raw material, the use of a unique process, the diamond powder and carbide matrix sintering at high temperature and pressure, diamond Layer and carbide layer is firmly bonded, diamond particles was D-D bond between the connection.our company produced PCD composite sheet diamond content of more than 90%, both with high hardness and wear resistance, but also has good impact toughness, is to achieve the ideal composite superhard material to automotive grinding, high efficiency and low cost cutting.Widely used in the processing of copper, aluminum and other non-ferrous metals and various types of alloy materials, wood, laminate flooring, graphite, rubber, plastics, ceramics, refractories and other high hardness and difficult processing of composite materials, can also be used in the manufacture of testing equipment and other equipment support, guide wear parts.And according to user needs, the product processing into a square, triangular, fan-shaped and other shapes

Product

range

Diamond micron

particle Size (um)

Diamond

content (%)

Product Features

Scope of application

PCD-02

2

>92

Excellent surface finish, high impact toughness, wear resistance in general, good electrical conductivity, EDM cutting.

Suitable for ultra-finishing copper, copper alloy, aluminum, magnesium, magnesium alloy, precious metal and processing requirements of the surface finish of the workpiece, such as automotive engines.

PCD-05

5

>92

High surface finish, high impact toughness, wear resistance than PCD-02, good conductivity, EDM cutting.

Suitable for ultra-finishing copper, copper alloy, aluminum, Aluminum alloy, magnesium, magnesium alloy, optical materials, plastic parts, plexiglass and so on.

PCD-10

10

>95

High surface finish, high impact toughness, high wear resistance, good conductivity, EDM cutting.

Suitable for high-speed finishing Aluminum alloy (silicon content of less than 13%), copper alloy, composite wood processing, high-precision wear-resistant support and so on.

PCD-25

25

>95

High wear resistance, good electrical conductivity, can be EDM.

Suitable for machining Aluminum alloy (silicon content greater than 13%), hard alloy, graphite and graphite composites, ceramics, carbide, non-metallic hard and brittle materials, laminate flooring, and other high wear-resistant materials.

PCD-302

2+30

>95

High wear resistance, good electrical conductivity, can be EDM.

Suitable for machining Aluminum alloy (silicon content greater than 13%), hard alloy, graphite and graphite composites, ceramics, carbide, non-metallic hard and brittle materials, laminate flooring, and other high wear-resistant materials.