Coated diamond and CBN is the use of chemical coated, electroplating coated and other methods of diamond, cubic boron nitride coated surface layer of a specific thickness of the metal layer, in order to improve the binding capacity of diamond, cubic boron nitride and binder, enhance the abrasive gripping force, to mask their own defects in the abrasive grains to improve the strength, thermal stability and chemical corrosion, while the metal coating can isolate the air, enhance, reduce Diamond, cubic boron nitride oxidation and thermal damage, significantly extend the life of grain and improve the application performance of diamond and CBN tools.

Product Features:

a. Coated series products include coated titanium, coated nickel, coated copper and other varieties.

b. Can be coated a variety of diamond and cubic boron nitride.

c. Mature and stable coated process to ensure that the plating layer is dense and uniform, not only can accurately control the plating layer thickness and the metal weight gain, also can be customer requirements to provide the two metals of the composite plated products.

d. Unique abrasive surface of the purification pre-treatment process to make the diamond, cubic boron nitride and the coating layer binding force is more solid.

e. Based on nano-powder dispersion and surface treatment experience, to ensure that the 10µm in finely plated products will not appear blocking phenomenon.

Available specifications:

a. Nickel coated products with conventional specifications have N30, N56 and N60 etc., can according to customer requirements coated different thickness of the plated layer.

b. Coated copper, coated titanium products according to customer requirements coated different thickness of the plated layer.

Areas of application:

a. Ti-coated diamond, cubic boron nitride are commonly used in metal and ceramic bond products.

b. Chemical nickel coated of diamond, cubic boron nitride are commonly used in resin bond and electroplated bond products.

c. Nickel plating of diamond, cubic boron nitride are commonly used in resin bond products.

d. Copper coated diamond, cubic boron nitride are commonly used in resin bond and metal bond products.

|

|

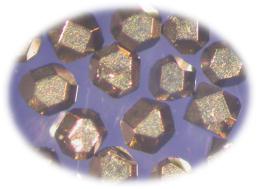

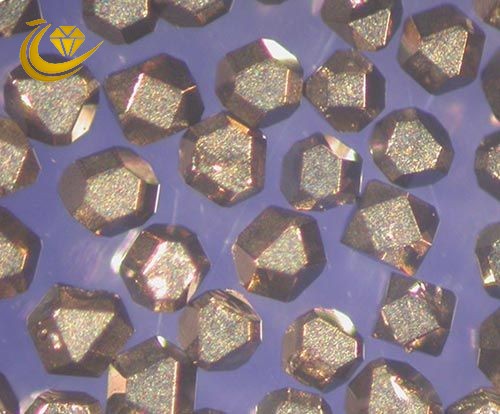

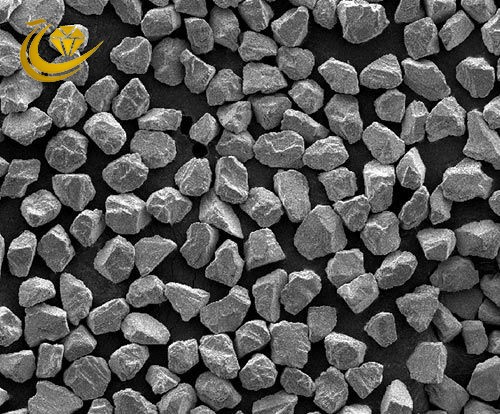

SD-Ti/CBN-Ti

Features: plating titanium products, so that the abrasive grain strength is more high, more high temperature, more resistant to chemical corrosion, the plating layer greatly enhanced the abrasive grain and the carcass of the mechanical connection, and enhance the abrasive grain and the carcass of the gripping force, but also to prevent the abrasive oxide and the metal erosion, greatly extend abrasive life and improve the diamond tools and CBN tools for the application performance.

Uses: widely used in ceramics binding agent and metal binding agent.

Specifications: according to customer requirements plating different thickness of the plating layer; plating each of the particle size of the abrasive and micro powder.

|

|

|

|

|

|

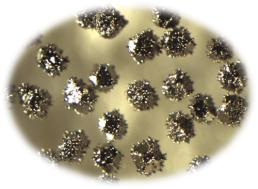

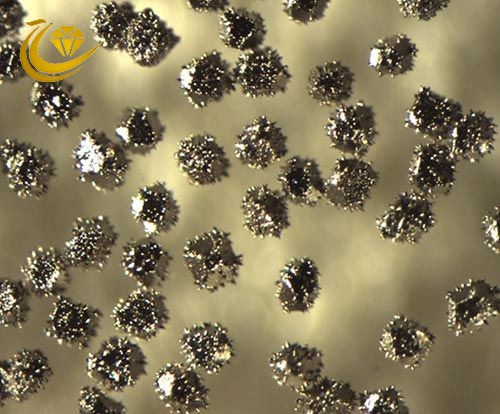

SD-ENi/CBN-ENi

Features: electroplating nickel products, thorn-like nickel alloy plating coating, can prevent the diamond from erosion, which can effectively improve the abrasive grain and the carcass of the gripping force, improve the grinding particle size of working height, thereby improving the cutting efficiency, extended tool life and sharpness.

Uses: widely used in resin bond and electroplated bond.

Specifications: according to customer requirements plating different thickness of the plating layer; plating each of the particle size of the abrasive and micro powder.

|

|

|

|

|

|

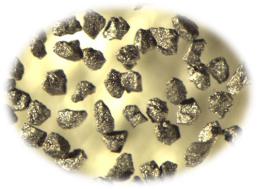

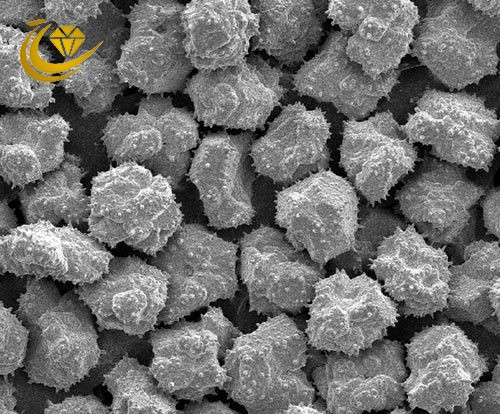

SD-CNi/CBN-CNi

Features: chemical nickel plating products, can greatly carcass with the abrasive gripping force, extend tool life and improve its sharpness.

Uses: widely applied to resin binding Agent.

Specifications: according to customer requirements plating different thickness of the plating layer; plating each of the particle size of the abrasive and micro powder.

|

|

|

|

|

|

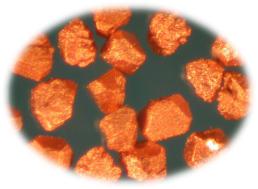

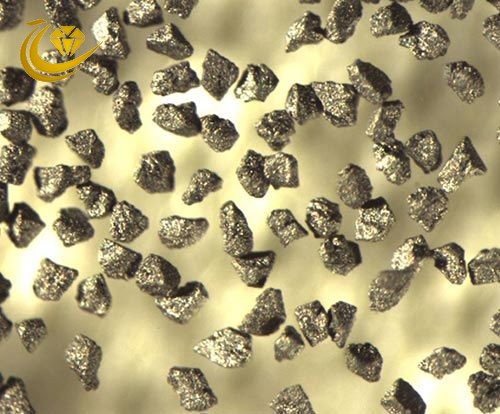

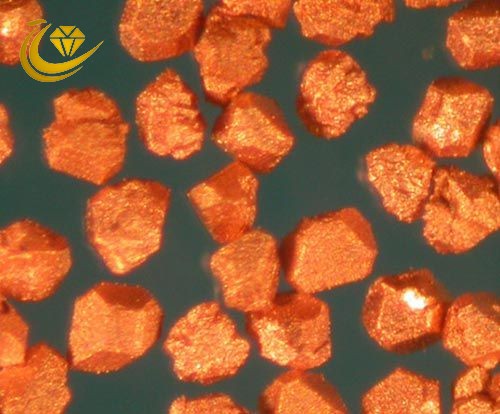

SD-Cu/CBN-Cu

Features: copper plating product can enhance the diamond and the carcass of the gripping force, improve heat dissipation, reduce heat loss, thereby extending tool life.

Uses: widely used in metal binding Agent.

Specifications: according to customer requirements plating different thickness of the plating layer; plating each of the particle size of the abrasive and micro powder.

|

简体中文

简体中文 English

English Pусский

Pусский

.jpg)

Description

Coated diamond and CBN is the use of chemical coated, electroplating coated and other methods of diamond, cubic boron nitride coated surface layer of a specific thickness of the metal layer, in order to improve the binding capacity of diamond, cubic boron nitride and binder, enhance the abrasive gripping force, to mask their own defects in the abrasive grains to improve the strength, thermal stability and chemical corrosion, while the metal coating can isolate the air, enhance, reduce Diamond, cubic boron nitride oxidation and thermal damage, significantly extend the life of grain and improve the application performance of diamond and CBN tools.

Product Features:

a. Coated series products include coated titanium, coated nickel, coated copper and other varieties.

b. Can be coated a variety of diamond and cubic boron nitride.

c. Mature and stable coated process to ensure that the plating layer is dense and uniform, not only can accurately control the plating layer thickness and the metal weight gain, also can be customer requirements to provide the two metals of the composite plated products.

d. Unique abrasive surface of the purification pre-treatment process to make the diamond, cubic boron nitride and the coating layer binding force is more solid.

e. Based on nano-powder dispersion and surface treatment experience, to ensure that the 10µm in finely plated products will not appear blocking phenomenon.

Available specifications:

a. Nickel coated products with conventional specifications have N30, N56 and N60 etc., can according to customer requirements coated different thickness of the plated layer.

b. Coated copper, coated titanium products according to customer requirements coated different thickness of the plated layer.

Areas of application:

a. Ti-coated diamond, cubic boron nitride are commonly used in metal and ceramic bond products.

b. Chemical nickel coated of diamond, cubic boron nitride are commonly used in resin bond and electroplated bond products.

c. Nickel plating of diamond, cubic boron nitride are commonly used in resin bond products.

d. Copper coated diamond, cubic boron nitride are commonly used in resin bond and metal bond products.

SD-Ti/CBN-Ti

Features: plating titanium products, so that the abrasive grain strength is more high, more high temperature, more resistant to chemical corrosion, the plating layer greatly enhanced the abrasive grain and the carcass of the mechanical connection, and enhance the abrasive grain and the carcass of the gripping force, but also to prevent the abrasive oxide and the metal erosion, greatly extend abrasive life and improve the diamond tools and CBN tools for the application performance.

Uses: widely used in ceramics binding agent and metal binding agent.

Specifications: according to customer requirements plating different thickness of the plating layer; plating each of the particle size of the abrasive and micro powder.

SD-ENi/CBN-ENi

Features: electroplating nickel products, thorn-like nickel alloy plating coating, can prevent the diamond from erosion, which can effectively improve the abrasive grain and the carcass of the gripping force, improve the grinding particle size of working height, thereby improving the cutting efficiency, extended tool life and sharpness.

Uses: widely used in resin bond and electroplated bond.

Specifications: according to customer requirements plating different thickness of the plating layer; plating each of the particle size of the abrasive and micro powder.

SD-CNi/CBN-CNi

Features: chemical nickel plating products, can greatly carcass with the abrasive gripping force, extend tool life and improve its sharpness.

Uses: widely applied to resin binding Agent.

Specifications: according to customer requirements plating different thickness of the plating layer; plating each of the particle size of the abrasive and micro powder.

SD-Cu/CBN-Cu

Features: copper plating product can enhance the diamond and the carcass of the gripping force, improve heat dissipation, reduce heat loss, thereby extending tool life.

Uses: widely used in metal binding Agent.

Specifications: according to customer requirements plating different thickness of the plating layer; plating each of the particle size of the abrasive and micro powder.