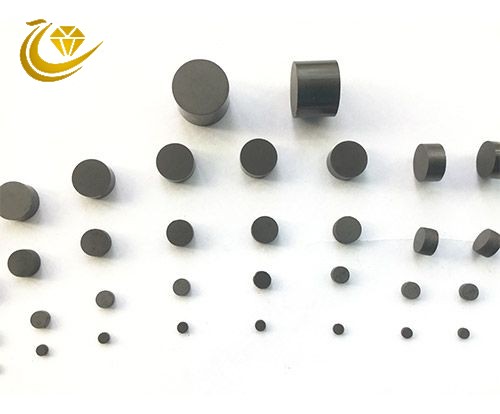

PCD Blanks for Wire Drawing Dies

PCD Blanks for Wire Drawing Dies is a diamond powder under the action of binding agent, high temperature and pressure sintering process.In the sintering process, the formation of high-strength diamond bond between diamond microcrystalline particles, the diamond powder particles strongly bonded together to form polycrystalline diamond......

We're here to help:Easy ways to get the answers you need.

PRODUCT LIST

- Single crystal superhard material

- Large Single Crystal Diamond Big Size Single Crystal Diamond BCD seriesSingle Crystal Diamond Plates SCDP series

- Single Crystal Diamond Coarse Synthetic Diamond CSD seriesFine Synthetic Diamond FSD seriesResin Bond Diamond AC series

- Crushed & Reshaped Diamond Powder Crushed Diamond Powder CCSD seriesReshaped Diamond Powder RCSD seriesPolycrystalline Diamond Abrasives APC4 series

- Diamond Micron Powder General Diamond Micron Powder CSDM seriesSpecial Diamond Micron Powder CSDM series As Grown Diamond Micron Powder ASM series Polycrystalline Diamond Micron Powder CSDM-PD series

- CBN (Cubic Boron Nitride) CBN MonocrystalCBN Micron Powder

- Coated Diamond and CBN Coated Diamond and CBN

- Polycrystalline Superhard Materials

- PCD (Polycrystalline Diamond) PCD Blanks for Wire Drawing DiesPCD Wire Drawing DiesPCD Blanks for Cutting ToolsPCD Cutting Tools

- PDC (Polycrystalline Diamond) PDC Cutters for Oil & GasPDC Cutters for MiningPDC Cutters for StoneThermally Stable PCD(TSP)

- PCBN (Polycrystalline Cubic Boron Nitride) Solid PCBN Cutting ToolsCarbide Supported PCBN CompactsPCBN Soldering Cutting Tools

- CVD Diamond CVD Blanks for Wire Drawing DiesCVD Blanks for DressingCVD Blanks for Cutting ToolsCVD Blanks for Thermal ManagementCVD Blanks for Optical Windows

Size Chart

|

ADDMA |

Product Code |

Size (mm) |

Size (μm) |

Schematic |

||||||||

|

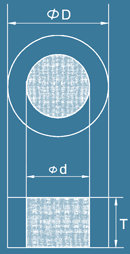

Outer dia of die blanksΦD |

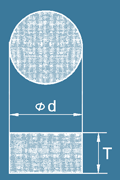

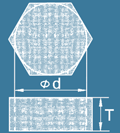

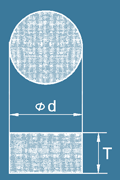

Diamond Dia. Φd |

Diamond Thickness T |

Max Recommended Aperture |

|

|

|

|

.jpg) |

|

|||

|

1 |

3 |

5 |

10 |

15 |

25 |

|||||||

|

TCD Series |

|

|||||||||||

|

T12 |

TCD4015 |

8.12 |

4.0 |

1.5 |

1.0 |

○ |

● |

● |

● |

● |

● |

|

|

T15 |

TCD4023 |

8.12 |

4.0 |

2.3 |

1.8 |

○ |

● |

● |

● |

● |

● |

|

|

T18 |

TCD4029 |

8.12 |

4.0 |

2.9 |

2.3 |

○ |

● |

● |

● |

● |

● |

|

|

T21 |

TCD7040 |

13.65 |

7.0 |

4.0 |

3.5 |

﹣ |

● |

● |

● |

● |

● |

|

|

T24 |

TCD7053 |

13.65 |

7.0 |

5.3 |

4.6 |

﹣ |

● |

● |

● |

● |

● |

|

|

T27 |

TCD13086 |

24.13 |

13.0 |

8.6 |

5.8 |

﹣ |

﹣ |

● |

● |

● |

● |

|

|

T30 |

TCD130116 |

24.13 |

13.0 |

11.6 |

7.8 |

﹣ |

﹣ |

○ |

● |

● |

● |

|

|

T31 |

TCD150120 |

24.13 |

15.0 |

12.0 |

9.0 |

﹣ |

﹣ |

﹣ |

○ |

● |

● |

|

|

T33 |

TCD150150 |

26.80 |

15.2 |

15.0 |

10 |

﹣ |

﹣ |

﹣ |

﹣ |

● |

● |

|

|

T33 |

TCD180150 |

29.00 |

18.50 |

15.0 |

11 |

﹣ |

﹣ |

﹣ |

﹣ |

● |

● |

|

|

TCD180180 |

29.00 |

18.50 |

18.0 |

12 |

﹣ |

﹣ |

﹣ |

﹣ |

● |

● |

||

|

TCD250180 |

36.00 |

25.00 |

18.0 |

14 |

﹣ |

﹣ |

﹣ |

﹣ |

○ |

○ |

||

|

TCD300200 |

41.00 |

30.00 |

20.0 |

16 |

﹣ |

﹣ |

﹣ |

﹣ |

○ |

○ |

||

|

CDR Series (Circular) |

|

|||||||||||

|

D6 |

CDR2510 |

2.5 |

1.0 |

0.4 |

○ |

● |

● |

● |

● |

● |

||

|

D12 |

CDR3215 |

3.2 |

1.5 |

1.0 |

○ |

● |

● |

● |

● |

● |

||

|

D15 |

CDR5225 |

5.2 |

2.5 |

1.5 |

○ |

● |

● |

● |

● |

● |

||

|

D18 |

CDR5235 |

5.2 |

3.5 |

2.0 |

○ |

● |

● |

● |

● |

● |

||

|

D21 |

CDR8040 |

8.0 |

4.0 |

3.0 |

﹣ |

● |

● |

● |

● |

● |

||

|

D24 |

CDR9853 |

9.8 |

5.3 |

4.0 |

﹣ |

● |

● |

● |

● |

● |

||

|

D27 |

CDR13085 |

13.0 |

8.5 |

5.0 |

﹣ |

﹣ |

○ |

● |

● |

● |

||

|

D30 |

CDR160120 |

16.0 |

12.0 |

7.0 |

﹣ |

﹣ |

○ |

● |

● |

● |

||

|

D33 |

CDR180120 |

18.0 |

12.0 |

8.0 |

﹣ |

﹣ |

○ |

● |

● |

● |

||

|

D33 |

CDR180150 |

18.0 |

15.0 |

8.5 |

﹣ |

﹣ |

○ |

● |

● |

● |

||

|

CDR220100 |

22.0 |

10.0 |

9.0 |

﹣ |

﹣ |

○ |

● |

● |

● |

|||

|

CDR220150 |

22.0 |

15.0 |

9.5 |

﹣ |

﹣ |

○ |

● |

● |

● |

|||

|

CDH Series (Square) |

|

|||||||||||

|

D6 |

CDH2510 |

2.5 |

1.0 |

0.4 |

○ |

● |

● |

● |

● |

● |

||

|

D12 |

CDH3215 |

3.2 |

1.5 |

1.0 |

○ |

● |

● |

● |

● |

● |

||

|

D15 |

CDH5225 |

5.2 |

2.5 |

1.5 |

○ |

● |

● |

● |

● |

● |

||

|

D18 |

CDH5235 |

5.2 |

3.5 |

2.0 |

○ |

● |

● |

● |

● |

● |

||

|

SDR Series (Circular) |

|

|||||||||||

|

SDR220140 |

22.0 |

14.0 |

11.0 |

- |

- |

- |

- |

● |

● |

|||

|

SDR240160 |

24.0 |

16.0 |

12.0 |

- |

- |

- |

- |

● |

● |

|||

|

SDR260160 |

26.0 |

16.0 |

13.0 |

- |

- |

- |

- |

● |

● |

|||

|

SDR280160 |

28.0 |

16.0 |

14.0 |

- |

- |

- |

- |

● |

● |

|||

|

SDR300180 |

30.0 |

18.0 |

15.0 |

- |

- |

- |

- |

● |

● |

|||

|

SDR320180 |

32.0 |

18.0 |

16.0 |

- |

- |

- |

- |

● |

● |

|||

Description:

1) ● Stock Item ○ Order Product

2)The maximum recommended Aperture suitable for non-ferrous metals, soft wire, hard wire diameter can not exceed the recommended Aperture 65 per cent.

Comparison

Inquiry

PRODUCTS:

Copyright © 2018 Henan Baililai Superhard Materials Co., Ltd. All rights reserved. Powered by MetInfo

TOP

简体中文

简体中文 English

English Pусский

Pусский

.jpg)

Description

PCD Blanks for Wire Drawing Dies is a diamond powder under the action of binding agent, high temperature and pressure sintering process.In the sintering process, the formation of high-strength diamond bond between diamond microcrystalline particles, the diamond powder particles strongly bonded together to form polycrystalline diamond (PCD). PCD diamond wire drawing die blank, both high wear resistance, hardness and thermal conductivity, but also has good mechanical strength and toughness, suitable for drawing copper, aluminum, nickel, tungsten and other non-ferrous metals, stainless steel and various alloy wire rod pipe.

Our company PCD wire drawing die blank is divided into TCD, CD and SD three series, according to the needs of drawing applications, each series has 1 micron, 3 micron, 5 micron, 10 micron, 15 micron and 2 O micron size of wire drawing die blank for users to choose

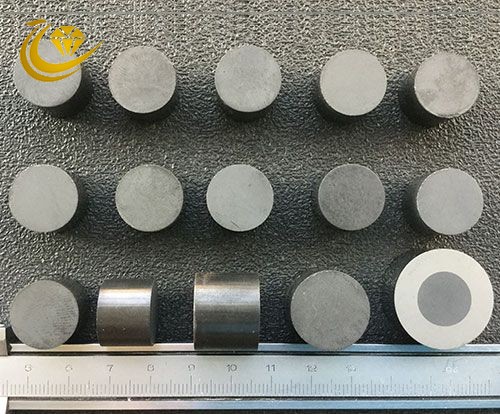

TCD Series

Features: diamond powder in the cobalt-based binding agent under high temperature and pressure process diamond powder and carbide support ring closely sintered as a whole, by the support ring to improve the crack strength of the mold, so this type of product can withstand higher strength and speed drawing, drawing high finish, TCD series mold blank to be below 650℃inlay sleeve, electric spark, laser and ultrasonic drilling and other methods.

Uses: suitable for high-speed drawing copper, aluminum, nickel, tungsten and other non-ferrous metals, stainless steel and all kinds of alloy wire rod and other hard materials and thicker materials

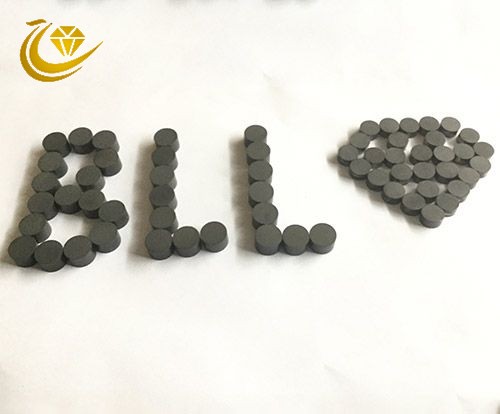

CD Series

Features: diamond powder in the cobalt-based binding agent under high temperature and pressure sintering process, no cemented carbide outer support, drawing high finish, CD series mold blank must be below 650℃inlay sleeve, available EDM, laser and ultrasonic drilling molding methods, CD series is divided into CDR (round)and CDH (hexagonal) two.

Uses: suitable for drawing copper, aluminum, nickel, tungsten and other non-ferrous metals and all kinds of alloy wire rod and other hard materials and smaller diameter material.

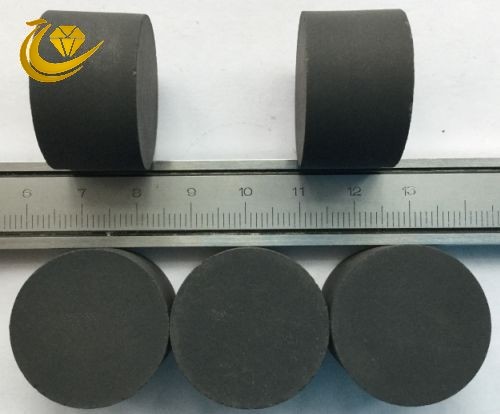

SD Series

Features: diamond powder in the silicon binding agent under high temperature and pressure sintering process, SD series moldings can be set at 1000℃ temperature, non-conductive, non-electric spark drilling molding.

Uses: suitable for drawing copper, aluminum wire mold, and the consumption of base metals, such as wire, wire and so on.