There are mainly two kinds of preparation of synthetic single Crystal Diamond of the method: one is the high-temperature high-pressure method high temperature and high pressure, is referred to as HTHP; the other one is the chemical vapor deposition method chemical vapor deposition,and referred to as CVD.

High temperature and pressure(HTHP method of synthetic diamond

High-temperature high-pressure method refers to a temperature more than 1500℃, a pressure of more than 109 Pa under the conditions of preparation of diamond-like method, the abroad is generally referred to as a temperature gradient method, the domestic is called the temperature difference method. HTHP method, there are currently two devices available for the preparation of a diamond: one is to use a six-sided top pressure machine, it is primarily the graphite offset the carbon converted into Diamond offset carbon; in addition a device is a two-stage ball-pressure machine the device, it's by the Soviet scientists Boris Feigelson et al in the early 90's developed.

Currently the industry is still primarily using the HTHP method to prepare single Crystal Diamond, which is the most significant point is that the manufacturing process is relatively simple, the diamond growth rate is fast, usually in 10-20min will be able to synthesize a 1mm or less Diamond single crystal, in order to meet various industrial needs. With the growth the development of technology, now through control of the generated core can be the growth of the particle size up to 2mm Diamond.

A chemical vapor deposition method

Chemical vapor deposition(CVD)the main use is in high temperature space is also included in the substrate and the active space occurs in a chemical reaction. The preparation of the diamond used in the raw material gas is generally methane and hydrogen, by the high temperature conditions under the excitation of the gas decomposition occurs, generating a carbon-containing group of the active particles, and ultimately in the substrate material deposited on the diamond film. Preparation of single-Crystal Diamond of the main methods of Microwave plasma-assisted chemical vapor deposition method, hot filament assisted chemical vapor deposition method, an electron cyclotron resonance Microwave plasma chemical vapor deposition method, the DC plasma jet chemical vapor deposition method, the combustion flame chemical vapor deposition method or the like.

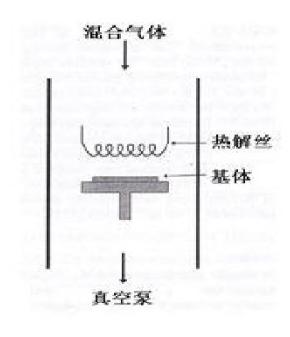

Chemical vapor deposition---hot filament-assisted chemical vapor deposition(HFCVD)

Mixed gas into the reaction chamber through the hot wire region reaches the collective surface, of molecular hydrogen on the hot filament surface catalyzed decomposition. The reaction zone only by a hot wire around a very small area of the composition, which makes the single filament of the scope has been limited, and the heat filament and the substrate between the best distance is 1-10mm. This process range with these smaller activation regions concerned, and the large-area deposition just by in the reaction chamber using a plurality of filaments to complete. The hot wire can be used W, Mo, etc., is usually heated to a temperature of from 2000 ° C to 2400 ° C, The reaction chamber at a typical pressure is 50Torr,HFCVD Diamond growth rate from 0. 1µm/h to 15µm/h. The deposition area from a few square millimeters to 300cm2 . The technology's main disadvantage is that Diamond film thickness and quality is uneven.

Prev:The diamond structure

Next:Diamond profile

PRODUCTS:

Copyright © 2018 Henan Baililai Superhard Materials Co., Ltd. All rights reserved. Powered by MetInfo

TOP

简体中文

简体中文 English

English Pусский

Pусский

.jpg)