Wire Wire

Solar Photovoltaic

Our wafer cutting solution: Wafer cutting is a key part of the solar photovoltaic cell manufacturing process. Our metal bond wire saw micro powder, resin bond diamond wire saw micro powder and related plating products can help customers solve This problem, and the use of good results, by the customer's praise! Our professional solutions can meet the high efficiency, long-life processing requirements of wire cutting, cutting sheets and other related efficient wafer cutting, good cutting surface quality, less surface scratches, and the combination of multi-size abrasive particles and various bonding agents. Can meet different processing needs.

Our silicon wafer thinning and grinding diamond solutions: We offer ceramic bond and resin bond diamond series according to customers' different processing and end application requirements, and provide customized products according to strength and crystal form. During the processing of silicon wafers, there are generally coarse grinding and fine grinding. When rough grinding, the diamond on the grinding wheel is thicker. When fine grinding, fine-grained diamond is used. The ceramic bonding agent is mainly used for rough grinding processing and resin bonding agent. For semi-finishing, customers can choose different diamond bond abrasives according to the processing requirements.

Magnetic Material

We offer high quality metal bond and resin bond diamond series for grinding hard and soft magnetic oxygen, whether it is cutting, grooving, profile grinding, flat grinding, double face grinding, vertical grinding or Coreless grinding is a success. It can be applied to various soft and hard magnetic materials such as ferrite, iron cobalt nickel alloy, aluminum nickel cobalt, neodymium iron boron. The product has the characteristics of good sharpness, good durability and good heat resistance, and is very suitable for various dry grinding and wet grinding environments. It is the best choice for your magnetic material grinding process.

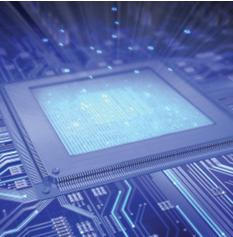

Semiconductor Industry Applications

The electronic information industry is the leader of the national economy, and the integrated circuit is the core and foundation of the electronic information industry, which has important strategic significance for the country's economic development.

At present, more than 95% of semiconductor devices and more than 99% of integrated circuits are made of silicon materials, in order to meet the requirements of chip miniaturization, high density, high digitization and system integration, chip diameter, flattening line width and The number of metal interconnect layers puts higher requirements, which also puts higher demands on precision machining of wafers. Our metal bond diamond and resin bond diamond and related plating products series provide precise customized service for the complete industrial chain.

一.We provide special powder for diamond grinding wheel for silicon wafer processing.

In the manufacture of silicon-based semiconductor devices, diamond wheel grinding has two main uses:

On the one hand, it can be used for the etching of silicon wafers, in order to improve the flatness of the silicon wafers in the wafer library delivered to the polishing process, and to reduce the amount of wafer removal in the polishing process.

Another use is to thin the thickness of the wafer as a whole before the dicing process. As market demand for smart cards and smart labels grows, so does the need for thin, flexible wafers, which requires more back grinding.

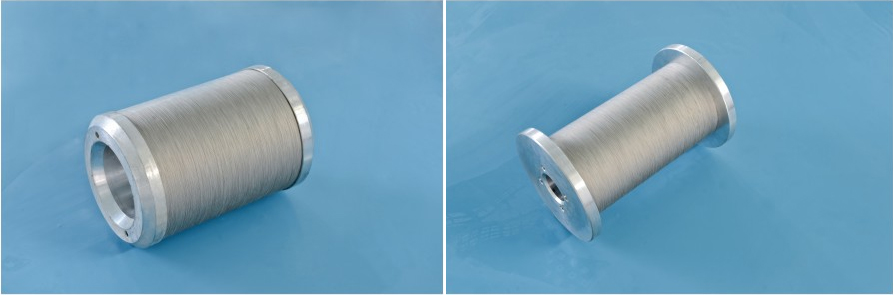

二.We provide silicon square, cut off, cut silicon core with diamond wire saw custom powder

The cutting of diamond wire can improve the silicon opening and cutting capacity, and is the best substitute for traditional mortar cutting.

Product Advantages:

1. The cutting speed is fast, and the cutting speed is one times the cutting of the mortar.

2. Clean and efficient production.

3. Lower consumption compared to traditional mortar cutting, and lower electricity and water consumption during production.

4. The quality is stable and the reproducibility is good.

5. Good cutting precision and good cutting surface quality.

6. There are few surface marks.

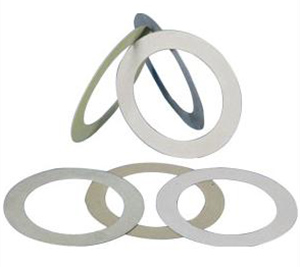

三.We provide wafer chamfering and round side grinding wheel special diamond powder

The outer edge of the wafer cut by the wire-cut or inner-circle saw blade is very sharp.In order to avoid the impact of the corner cracking on the wafer strength, damage the surface smoothness and pollution to the subsequent process, it must be automatically trimmed with special numerical control equipment. Wafer edge, outline and outer diameter.

Silicon ingot grinding wheel for solar cell, resin, metal bond type grinding wheel for surface grinding, suitable for high efficiency machining of silicon ingot.

四.We provide special diamond powder for wafer backside thinning wheel

The back side of the wafer is thinned and ground by a diamond grinding wheel for rough grinding, which is divided into rough grinding and fine grinding. When rough grinding, the diamond of the grinding wheel is relatively thick. This type of grinding wheel includes two types of ceramic bonding agent and resin bonding agent. It is mainly used for thinning and grinding of wafer back or front silicon wafer in integrated circuit and discrete device manufacturing process. Among them, ceramic binder is mainly used for rough grinding, and resin binder is used for semi-static grinding and fine grinding.

五.We provide special diamond powder for wafer dicing blade.

Our resin binder and metal bond diamond powder can meet the precision cutting requirements of the front and back dicing processes, and the ultra-fine powder abrasive uniform dispersion technology can be used for difficult chamfering and step cutting processing in customer applications. It exhibits high toughness, high precision, ultra-thin, long life and easy to use.

Our FSD synthetic diamond fines, diamond crushing materials, diamond micro-powders, diamond drawing die are widely used in the electronics and electrical industry.

Prev:Optical Industry

Next:Geological Drilling

PRODUCTS:

Copyright © 2018 Henan Baililai Superhard Materials Co., Ltd. All rights reserved. Powered by MetInfo

TOP

简体中文

简体中文 English

English Pусский

Pусский

.jpg)