Glass Processing

Glass processing involves grooving, cutting, chamfering, drilling, edging, grinding, polishing and other processes, should be used in diamond tools, such as: resin grinding wheel, drill bit, grinding head, grinding wheel, polishing wheel, polishing fluid, etc., and these diamond tools are inseparable from our Diamond, so we can according to the specific needs of customers, help customers to develop the most appropriate solutions.

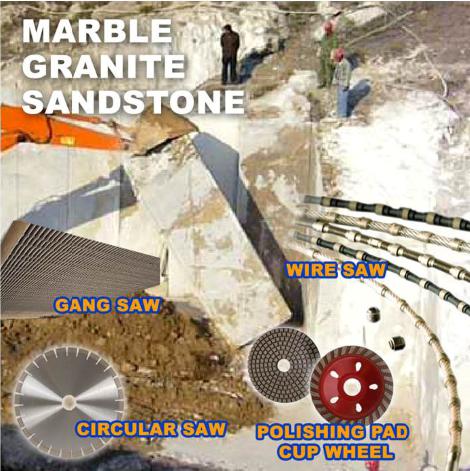

Stone Processing

In order to maximize the potential needs of our customers, we not only provide high-end MBD-coated diamond for increased grip and tool life, but also offer a wide range of synthetic diamond products of different intensities and sizes to meet the needs of our customers for higher performance and lower production costs, as well as the opportunity to develop new end-user applications.

Our Cutting Blade Solutions For Construction And Stone

A more durable cutting material means lower costs for the tool and the end user, and a gradual increase in productivity can help customers improve the performance of finished tools and reduce tooling manufacturing costs.

We have successfully developed a more gripping MBD synthetic diamond abrasive, with excellent thermal stability to cope with a variety of different hardness aggregates, products for sawing, cutting, grinding, polishing, Foundation drilling, trenching, wall cutting, tunneling and soil reinforcement to provide the best performance.

Our Stone And Mud Polishing Solutions

In order to meet the consumer's aesthetic view, the stone industry needs to cut the plate further polished polished, we provide a metal bonding agent for grinding block powder, with sharpness, long life, high efficiency, high efficiency, widely used in the terrazzo floor, marble, granite, refractory brick, terrazzo and mixed clay products and other non-metallic brittle materials efficient grinding and polishing.

Ceramic Industry

|

|

Our ceramic solution is to provide system-of metal-binding Agent, resin-binding Agent, ceramic-binding Agent powder and related plating products. In general grinding, the choice of 80 ~ 120 mesh, semi-fine grinding 120 ~ 180 mesh, fine grinding select 180 mesh-W40, resin binder abrasive selection of 50% ~ 100% concentration, Bronze binder abrasive selection of 75% ~ 150%concentration, coarse size, high-efficiency grinding and grinding when forming a high concentration should be used. | |

|

|

Metal bonding agent is mainly used for coarse grinding, resin bonding agent is mainly used for grinding, ceramic bonding Agent Diamond grinding wheel has high strength, good heat resistance, sharp cutting, high grinding efficiency, grinding process is not easy to heat and blockage, thermal expansion small amount, in order to control the processing accuracy. Compared with the resin binder wheel, he solved the resin Diamond wheel low life, low grinding efficiency, abrasive grinding process itself variability problems. |

Our CSD diamond coarse materials are widely used in the manufacture of diamond saw blades and wire saws for cutting stone, reinforced concrete and other building materials; FSD diamond fine materials are widely used in the manufacture of diamond saw blades and drill bits for cutting glass, ceramics and other building materials; diamond crushing materials It is widely used in the manufacture of diamond grinding tools for polishing stone, glass, ceramics and other building materials.

Prev:Machining Industry

Next:Optical Industry

PRODUCTS:

Copyright © 2018 Henan Baililai Superhard Materials Co., Ltd. All rights reserved. Powered by MetInfo

TOP

简体中文

简体中文 English

English Pусский

Pусский

.jpg)