High-Speed Railway Applications

High-speed railway rail grinding is a new issue for our country, the wheel-rail power caused by the uneven track, The impact on the road safety, smooth and ride comfort along with the increase in vehicle speed and significantly increased. For high-speed rail, some of the rail surface is not smooth do not say the train comfort is reduced, and may even lead to the destruction of the track and the vehicle and even the occurrence of road accidents, which must be strictly controlled.

Rail is the main component of rail transportation, rail and train wheels in direct contact, its quality directly affects the safety and stability of the road. After the opening of the rail transit operation, the rail will be in the long-term in the harsh environment, due to the dynamic effects of the train, the natural environment and the quality of the rail itself and other reasons, the rail damage often occur, such as cracks, wear and other phenomena, resulting in the rail life is reduced, increased maintenance workload, increased maintenance costs, and even seriously affect the safety of the road.

Therefore, it is necessary for immediate rail damage to eliminate or repair, in order to avoid affecting the safety of rail traffic operation. These repair measures such as rail oil, rail grinding, which polished rail because of its efficiency by the world's railway widely used.

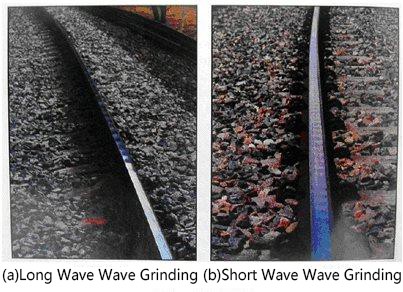

In order to prolong the service life of the rail in the heavy railway, the rail grinding form has also developed from the initial repair to the maintenance of the grinding development to the present particularly popular “Frequent, rapid, mild ”preventive grinding. Also high-speed railway also carries out maintenance and repair of rail grinding. The new rail after the implementation of the new high-speed rail paving polished for the first time for the new rail polished, is another type of grinding, called "rail pre-grinding" that is preliminary grinding, it is completely different from the operation of the process of preventive rail grinding.

Rail grinding technology after years of application development, has been widely used in high-speed rail, heavy rail and urban Rail Transit rail maintenance and repair, effectively extending the service life of the rail. In the application process, you need to pay attention to the following:

1) rail grinding requirements (rail short-term life or rail long-term life)

2) The purpose of the use of rail grinding (reduce noise or reduce wear and damage)

3) Strategy adopted for rail grinding (grinding strategy , grinding times , grinding mode, etc . )

4) different grinding purposes, it is necessary to use different grinding strategy, while the effect of rail grinding requires a long observation.

Rail grinding is a relatively expensive means of operation, its application must be expected to obtain the economic benefits of the link. The effect of rail grinding is as follows:

1) increase the service life of the rail by 50% -100%

2) reduce the risk of rail failure

3) reduce the deterioration rate of wheels, rail parts and rail geometries

4) allow trains to run at higher speeds

5) reduce wheel rail noise.

When the grinding wheel as a grinding tool for the job, are rigid contact between the wheel and rail, so the higher the grinding control technology requirements, and by its self-sharp grinding wheel to maintain a sharp rail cutting performance, grinding wheel formulations and manufacturing process requirements higher.

Elastic contact between the belt and steel, avoid rigid contact with the rail wheel, and the belt is coated abrasive, rail grinding process to improve the effective utilization of the abrasive. Belt grinding good heat dissipation, noise is small, will not happen when grinding rail surface burns, grinding tool crushing.

Preventatively polished rails and turnouts extend the service life of the rails from 3 to 5 years. Not only improve the quality of line equipment, reduce transportation costs, but also greatly improve the smooth operation of passenger trains, making passengers ride the train more comfortable.

Diamond, cubic boron nitride is the world's highest hardness of two materials, high hardness, wear resistance, use it as abrasive hard, brittle and other difficult workpiece, consumption is extremely small, not only to ensure the accuracy of the workpiece, but also improve the processing time, but also effectively solve the problem of environmental pollution. Therefore, the following trends: replace ordinary silicon carbide abrasive Diamond abrasive, CBN abrasive replace ordinary corundum abrasive.

Diamond belt: for stone, glass, ceramics, Monocrystalline silicon, polycrystalline silicon, synthetic materials, hard alloy, Aluminum alloy and other hard brittle material complex surface grinding and polishing process.

CBN belt: all kinds of iron-based alloy, titanium alloy, stainless steel, high-temperature alloy, (nickel-based and cobalt-based alloy) and other hard and difficult materials and complex shape of the workpiece grinding and polishing.

Prev:Medical Beauty

Next:No Information

PRODUCTS:

Copyright © 2018 Henan Baililai Superhard Materials Co., Ltd. All rights reserved. Powered by MetInfo

TOP

简体中文

简体中文 English

English Pусский

Pусский

.jpg)