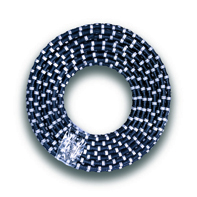

Diamond rope saws

The diamond wire saw is a cutting and dismantling tool for mines, blocks, curved plates, large slabs of stone, thick concrete, irregular concrete bars, bridges and roads. Easy to install, flexible to use, horizontal cutting, vertical cutting. It is a hydraulically driven power unit cutting device that can perform various cuttings on thick concrete. It is the most suitable cutting construction equipment for cutting and demolition of basements, chimneys and pillars. Wire saws are suitable for densely packed reinforced concrete structures, thick brick walls, and even underwater cutting operations. Wire saws can meet the cutting depth of hydraulic wall saws. The cutting operation depth is not limited, the working environment is more adaptable and the work efficiency is higher, and it is the backup equipment of the hydraulic wall saw machine.

According to the actual needs and uses, the wire saws on the market can be divided into 7 categories: concrete cutting wire saw, granite and mining wire saw, granite block plastic wire saw, granite shaped wire saw, marble mining rope Saw, marble block plastic wire saw, marble shaped wire saw, wire saw group saw. According to the material of the production, it can be divided into rubber wire saw, plastic wire saw, spring wire saw, and spring plus rubber wire saw (for concrete cutting). The wire saw specifications are mainly controlled by beading. The specifications can be from Φ6.3~Φ11.5, but the formula of different stones is different. The recipe of beading should be customized according to the actual situation of the stone. effectiveness.

Diamond saw blade

Diamond saw blade is a cutting tool widely used in the processing of hard and brittle materials such as concrete,refractory materials,stone,ceramics.The diamond saw blade is mainly composed of two parts; the base body and the cutter head. The base body is the main support part of the bonding cutter head,and the cutter head is the part which is cut during use,the cutter head is continuously consumed in use,and the base body does not,the cutter head can cut The role is because it contains diamond,diamond is the hardest material at present,it rubs and cuts the object to be processed in the cutter head, and the diamond particles are wrapped in the inside of the cutter head by metal powder.According to the process diamond saw blade,it can be divided into:

Prev:Single Crystal Diamond Tool

Next:Gem Processing

PRODUCTS:

Copyright © 2018 Henan Baililai Superhard Materials Co., Ltd. All rights reserved. Powered by MetInfo

TOP

简体中文

简体中文 English

English Pусский

Pусский

.jpg)